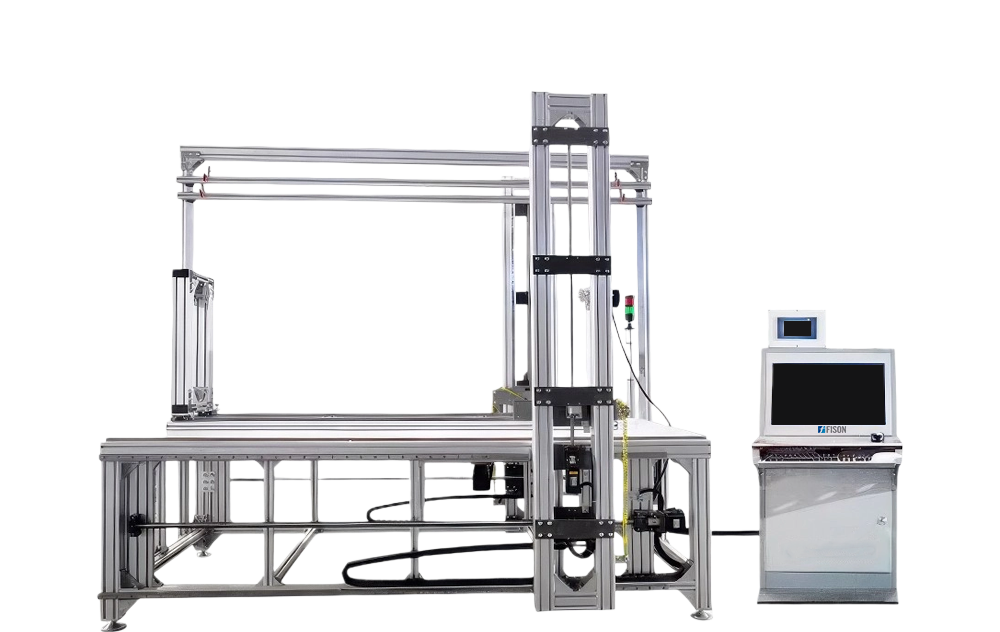

Universal testing instrument FM-UTM-A100

Universal Testing Instrument FM-UTM-A100 is a floor-mounted unit capable of handling forces up to 1000 kilonewtons (KN). It features hydraulic tensile grips with a built-in tightening mechanism . The device uses a spoke load sensor load cell for precise measurement accuracy. Various specimen sizes can be accommodated. It performs compression, bending, and shear tests on different materials

Specifications

| Maximum Capacity | 1000 KN |

| Force measurement sensor | Spoke load sensor |

| Length of testing area | 800 mm |

| Column distance | 610 mm |

| Piston stroke | 250 mm |

| Frame weight | 3350 kgs |

| Test Force ( Relative error ) | ± 1% or better accuracy (≤ ± 0.5% precision) |

| Deformation precision | ±1%(Or ± 0.5% precision) |

| Extension capacity | 650 mm |

| Compression capacity | ≥ 500 mm |

| Grip mechanism | Automatic clamping |

| Diameter of round samples | Φ26 to Φ 60 mm |

| Thickness of flat samples | 0 to 40 mm |

| Pump motor power | 1.5 KW |

| Power of beam movement power | 1 KW |

| Device of measuring changes in shape | Photoelectric encoder or electronic extensometer |

| Safety features | software and mechanical limit protection |

| Power supply | AC 220 V, 50 Hz |

| Dimension ( L × W × H ) | 1000 × 800 × 2335 mm |

| Dimension ( Oil source control cabinet ) | 1160 × 600 × 1350 mm |

| 01 box Packing dimension (W × D × H) | 1100 × 980 × 2550 mm |

| 02 box Packing dimension (W × D × H) | 1260 × 700 × 1480 mm |

| Gross weight ( Main instrument ) | 3250 kg |

Features

- Universal Testing Instrument with adjustable test space

- Test space for various samples

- Limit switches for control

- Computer interface for data handling

- Improved ergonomics

- Option for load sensor or oil pressure sensor

Applications

- Universal testing instruments are applicable in manufacturing, construction, rubber, biomedical, Electronics, Textiles, Pharmaceutical, Food and beverage , and plastics industries.

Accessories

- 10 mm Shear specimen

Maximum bending distance

204 × 204 Top and bottom platens (Φ160 mm)