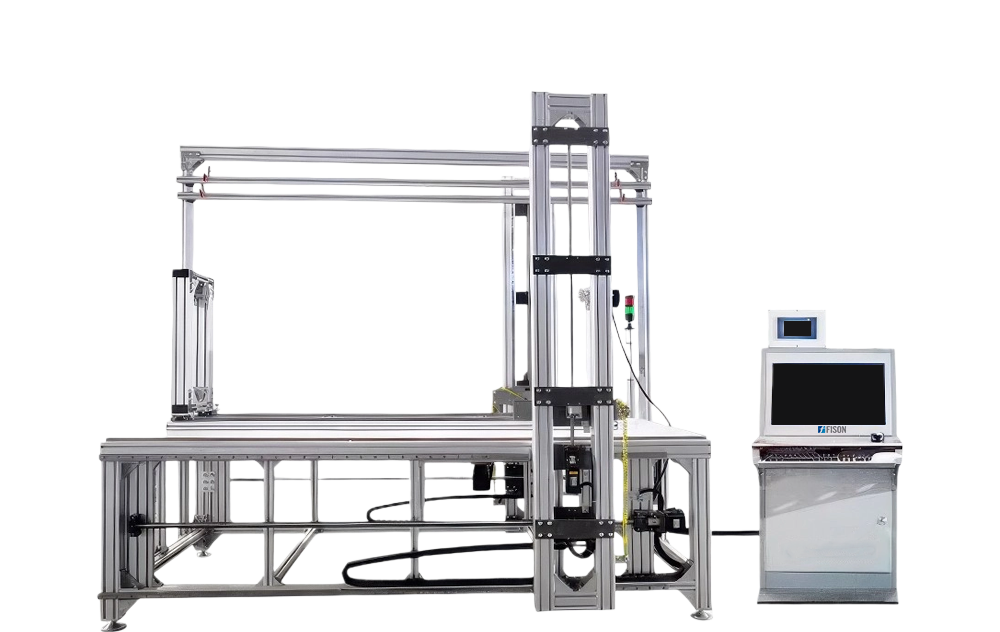

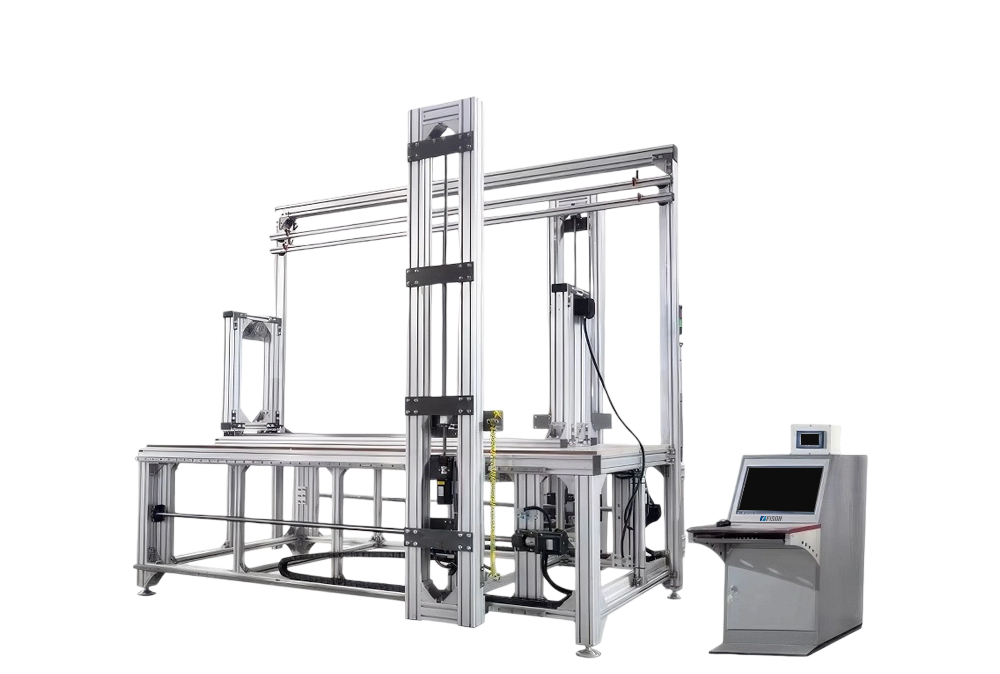

Foam Cutting Machine FM-FCM-A100

Foam Cutting Machine FM-FCM-A100 offers a cutting dimension of 2000×1250×1200 mm with 3D four-axis control for accuracy. It features ball screw transmission and uses nickel chromium alloy wire for precise cuts. It is lightweight, made of aluminium alloy, and supports asynchronous cutting for efficiency. With automated software integration, it ensures high-speed, adjustable cutting. It is ideal for industrial use, this machine combines precision, durability, and advanced technology.

Specifications

| Cutting dimension (L×B×H) | 2000×1250×1200 mm |

| Vertical arm cutting width | 1250 mm |

| Horizontal cutting distance | 2000 mm |

| Effective cutting height | 1200 mm |

| Cutting mode control | 3D two side asynchronous cutting |

| Controlling axis | 3D four axis |

| Transmission from | Ball screw drive |

| software | Auto CAD, CAXA |

| Speed | 2 mm/s |

| Host material | Section bar |

| Cutting curve | 0.4 mm nickel chromium alloy wire |

| Stepping motor | Shinnon-Japan |

| Power | 0.4 KW (excluding computer power) |

| Power supply | 380V, 50Hz |

| Dimension (L×B×H) | 2.5×1.5×2.4 m |

| Weight | 450 kg |

Features

- Adjustable cutting speed

- Gravity controlled wire feeding

- Auto typesetting system

- Low thermal expansion wire

Applications

- Foam Cutting Machine FM-FCM-A100 is perfect for lost foam casting and EPS mold shaping, widely used in foundries, automotive prototyping, and large-scale mold industries due to its high accuracy and efficiency.

Accessories

Accessories

Quantity

Industrial Touch Screen

1 set

Vertical Arms

1 set

Resistance Wire (20 m)

1 set

Spring

10 pcs

Parallel Port Line/LPT

1 pc

Bolt Bag

1 bag